Millwright Techserv Pvt Ltd: 12 Years of Experience

Millwright Techserv Pvt Ltd: 12 Years of Experience

The Complete CNC Solution Providers

Millwright is a CAD/CAM/CNC consulting company with a team of well experienced experts in the area of CNC machining started its operation in Chennai and catered all over the world and have a focused vision in providing manufacturing solutions, CAD/CAM/CNC Training and CNC Programming Services for manufacturing industries in different verticals like Automobile, Aerospace, Heavy engineering, Medical, Oil and Gas etc.

Millwright has a team of skilled and efficient engineers to provide services like CNC programming services, Skill development training on CNC shop floor in manufacturing industries, cycle time reduction on CNC machines, Programming transferring from PC to CNC machines vice versa, productivity monitoring systems, Application support on Swiss type and multi tasking machining, CAD designing services etc.

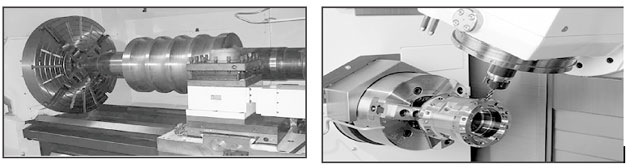

CNC Programming Services

Millwright TechServ Pvt Ltd do CNC Programming services for VMC, HMC, CNC lathes, VTL etc in all verticals like Automobile, Aerospace, Heavy engineering etc. It will more cost effective for small, medium and large scale companies, also they can avoid procurement costly CAD/CAM software's for rare developments, and also it saves their machine idle time due to programmer's unavailability CNC programming for CNC lathe, Vertical Machining centre, Horizontal Machining centre, VTLs, 4&5 Axis Machines, Detailed Cycle time Sheet, Tools List and Operation wise Machining Details.

Skill Development

Millwright TechServ Pvt Ltd can provide a tailor make Skill development training program for CNC Shop floor in machines like VMC, HMC, and VTLs etc for Fanuc and Siemens Controls, which will increase productivity and decrease machine idle time and damage by getting effective work output from and shop floor team.

- Fundamentals of CNC machines.

- Complete operating training on Fanuc and Siemens Controls on CNC lathe, Vertical Machining centre, Horizontal Machining centre, VTLs.

- Operation Settings like work offsets, tool offsets, etc.

- Basic Manual Programming for turning and milling operations.

- CAM software training.

Cycle Time Reduction

The company provide a software called CAPS turn, which improves CNC turning profitability by reducing CNC cycle time, programming time, setup time, and part rejections.

- Do Machining cost calculation

- Reduces machine downtime

- Reduces part rejections

- Reduces programming time

- Reduces tool cost

- Reduces damage to machine

- Reduces documentation time

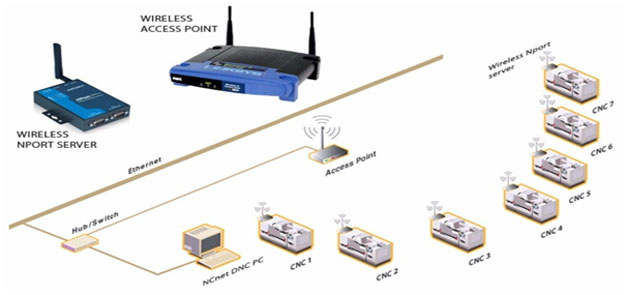

DNC (Direct Numerical Control)

The company provides Program transferring solutions between PC and multiple CNC Machines called NCnet, which reduces machine downtime for program transfer, part rejections due to outdated programs unauthorized access to programs and much more.

- Install DNC software and hardware on PC.

- Set up DNC parameters on the CNC machines and on PC as well.

- Establish DNC communication and demonstrate all functions of the Nc-net.

- Provide training on using DNC functions to your engineers.

- Document connectivity information and handover them.

Productivity Monitoring

The company also provide productivity monitoring system called LEANworks, which is a manufacturing execution system that increases profits by reducing machine downtime through unmanned wireless production monitoring, OEE calculation and reporting, predictive maintenance and part rejections tracking. It measures machine downtime and makes shop floor losses visible to the top-¬floor. One can reduce machine downtime by as much as 30% and can improve OEE by 24/7 OEE monitoring.

- Keep track of production quantity.

- Get production data on email or desktop.

- Track and improve OEE.

- Track and reduce part rejections.

- Reduce machine breakdowns.

- Identify and remove causes of idle times.

- Get alerts on SMS, respond before a crisis occurs.

- Improve Preventive maintenance, Predictive maintenance, Condition based maintenance.

- Track MTBF, MTTR.

- Standard and customized reports.

- Reports on email or on desktop or web.

- Hourly parts count from each machine.

- Graphical and tabular report formats.

- Machine downtime analysis.

- OEE trend and details.

- Maintenance reports - downtime, MTBF, MTTR.

Multi Tasking

The company provides a Solution for multi tasking machines by providing a software called Esprit, which act as a one stop solution for all multitasking machines dual spindle, dual turrets, axis configuration of A,B, C, X, Y, Z etc.

Perform simultaneous milling and turning operations, on the front and back of a part, in a single setup.

Supports any combination of independent, synchronized, and synchronous milling and turning utilizing any configuration of A, B, C, X, Y, and Z axes.

Supports mill-turn needs, including milling with full, simultaneous 3-axis and 5-axis 3D multi-surface solid machining.

Easily program the non-perpendicular multi-axis tool movements required to machine the intricate features and compound angles C and Y mill-turn capability, combining turning, milling, and drilling machining operations in one G-code program.

Gives you an extensive set of milling cycles including facing, pocketing, contouring, rest machining, hole making and more.

Swiss Type Machining

The company provides Solution for Swiss type machines by providing a software called Esprit, which act as a one stop solution for all Swiss and multitasking machines dual spindle, dual turrets, axis configuration of A,B, C, X, Y, Z etc.

- Program Swiss machines quickly

- Generate NC code correctly the first time

- Accurately quote the job for your machine

- Verify programs to minimize crashes

- Quickly generate set-up sheets and program information

CAD Designing Services

The company provides a CAD designing services like 2D to 3D conversion, reverse engineering, Fixture designing for manufacturing industries to reduce cost of new developments.

- Assembled fixture design.

- 2D sketch of Component seating.

- Reverse Engineering Model.

Millwright TechServ Pvt Ltd

#104/815A, MTH Road, Padi, Chennai – 600 050.

Mobile : +91 9840999411, 9094555565

Email: info@millwright.in | Website: www.millwright.in

Facebook

Facebook Plus Google

Plus Google Linkedin

Linkedin Twitter

Twitter